Ice & Water

Protector

Description

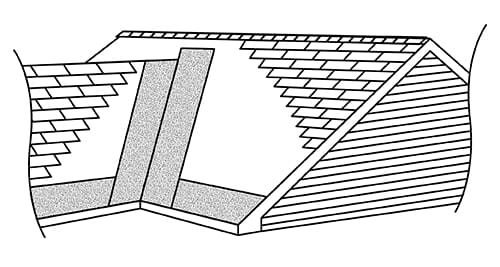

United Ice & Water Protector is used as a shingle underlayment on critical areas such as eaves, valleys, ridges, dormers and skylights. United Ice & Water Protector protects roofing structures and the building’s interior from water penetration caused by ice dams and wind driven rains. United Ice & Water Protector is a polymer modified asphalt membrane, fiberglass reinforced with a granular surface providing skid resistance during installation.

Preparation

Sweep roof deck to remove dirt and debris. The roof deck must be clean, smooth and free of moisture. If moisture is present it will limit or inhibit adhesion. On re-roofing, remove all old material from roof deck area to be covered with United Ice & Water Protector. Replace any damaged sheathing.

Weather Conditions

Apply when air temperature is over 40°F (5°C) but below 100°F (38°C). If applied in temperatures below 40°F (5°C), United Ice & Water Protector is stiffer and will not fully seal until it is warmed. If applied in temperatures above 100°F (38°C), it may become difficult to remove the release poly backing. If this situation should occur, move product to shaded area until cool. Once cooled, the release poly backing can be easily removed.

Installation

United Ice & Water Protector is applied directly to the surface of the roof deck. See carton for complete instructions and precautions.

COLD WEATHER INSTALLATION: Mechanically fasten membrane to position until it has bonded to the roof deck.

Advantages

- Protects structure from water seepage caused by wind driven rain and ice dams

- Self-Sealing: Seals around nails, staples and screws

- Self-Adhering: Bonds directly to the roof substrate

- Skid Resistant: Granular surface for safe and easy installation

Physical Properties

Slip Resistance

Tensile Strength

Elongation at Break (modified bitumen portion)

Moisture Vapor Permeance

Adhesion to Plywood, 40°F

Adhesion to Plywood, 73°F

Tear Resistance

Sealability Around Nail

Low Temperature Flexibility

Waterproofing Integrity after Low Temperature Flex

Waterproofing Integrity of Lap” col_column_max_width=”1fr” col_icon_size=”28px” col_tcell_cell_align_horz=”center” col_tcell_cell_align_vert=”center” col_rhead_cell_align_horz=”center” col_rhead_cell_align_vert=”center” _builder_version=”4.19.4″ _module_preset=”default” col_chead_text_font=”|||on|||||” col_chead_text_font_size=”17px” global_colors_info=”{}” theme_builder_area=”post_content”][/dvmd_table_maker_item][dvmd_table_maker_item col_label=”Feet per Pallet” col_content=”Test Method

Asphalt Saturated Felt

ASTM D412

ASTM D2523

ASTM E96

ASTM D1970/D903

ASTM D1970/D903

ASTM D4037

ASTM D1970

ASTM D1970

ASTM D1970

ASTM D1970″ col_column_max_width=”1fr” col_icon_size=”28px” col_tcell_cell_align_horz=”center” col_tcell_cell_align_vert=”center” col_rhead_cell_align_horz=”center” col_rhead_cell_align_vert=”center” _builder_version=”4.19.4″ _module_preset=”default” col_chead_text_font=”|||on|||||” col_chead_text_font_size=”17px” global_colors_info=”{}” theme_builder_area=”post_content”][/dvmd_table_maker_item][/dvmd_table_maker]

Applicable Standards & Codes

- ASTM D1970

- ASTM E108/UL 790 (Class A Fire Resistance)

Limitations

- Should not be applied over shingles or underlayment of any sort

- Should not be applied over damp surfaces

- Should not be left exposed to sunlight for more than 30 days (less if extreme heat conditions exist)

- Caution!! Surface can be slippery if wet or covered with frost

Properties

Coverage: 1.95 SQ Roll Covers Approx. 195 SF

Packaging: 1.95 SQ Roll 36/Pallet.

Specification: ASTM D-1970

Approximate Roll Weight: 1.95 Square 50 Lbs.

Membrane Width: Membrane 36”

Membrane Length: 1.95 Square Roll 65.0 Feet

Membrane Thickness: 53 mils

Application Method: Self Adhering

Surface Composition: Granules

Membrane Reinforcement: Fiberglass Mat

Backing Material: Silicone Coated Release Film

United Ice and Water Protector is a Self-Adhering & Skid Resistant granulated shingle underlayment which is used on eaves, valleys, ridges, dormers and skylights. United Ice & Water Protector is used to protect roofing structures from water penetration caused by ice dams and wind driven rain.

United High Temperature Ice and Water Protector is used under standing seam metal roofing, metal shingles and metal roof panels. This protects roofing structures from water penetration caused by ice dams and wind driven rain.

Where to Find our Products

Have Additional Questions About United Ice& Water Protector?

Have a product specialist reach out to answer any questions you may have.

Please fill out the below form completely and we’ll be happy to get in touch with you!