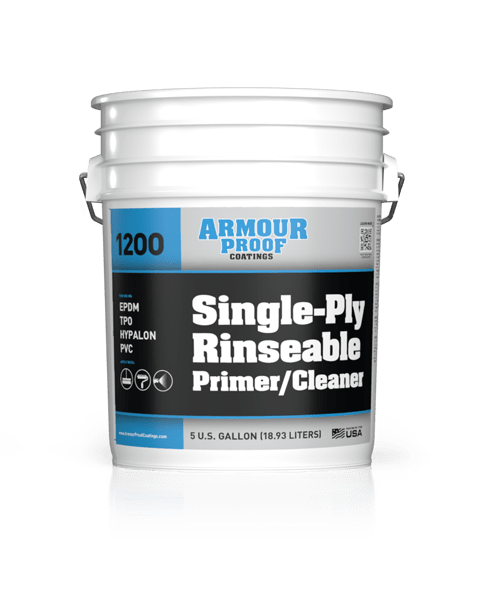

Single-Ply Roof Cleaner

AP-1200

Single-Ply Rinseable Primer / Cleaner

Prep your TPO, EPDM, PVC or Other Single-Ply Roof to Have the Best Surface to Coat!

Description

AP-1200 Single-Ply Rinseable Primer / Cleaner is a low viscosity, water-based rinseable cleaner. AP-1200 Single-Ply Rinseable Primer / Cleaner is designed to chemically alter the surface of new and weathered single-ply membranes by breaking down the chemical bond of the inorganics on the surface and to increase the adhesion of AP-3100, AP-3200 and AP-3300 roof coatings to the substrate.

designed to chemically alter the surface of new and weathered single-ply membranes by breaking down the chemical bond of the inorganics on the surface.

Color

Translucent / Pinkish” col_column_max_width=”1fr” col_icon_type=”||fa||900″ col_icon_size=”28px” col_icon_color=”#dcc9dd” col_tcell_cell_color=”RGBA(255,255,255,0)” col_tcell_cell_align_horz=”center” col_tcell_cell_align_vert=”center” col_chead_cell_color=”RGBA(255,255,255,0)” col_rhead_cell_align_horz=”center” col_rhead_cell_align_vert=”center” _builder_version=”4.20.2″ _module_preset=”default” col_tcell_text_font=”Lato||||||||” col_tcell_text_font_size=”21px” col_chead_text_font=”|||on|||||” col_chead_text_text_color=”#FFFFFF” hover_enabled=”0″ custom_css_col_icons=”font-size:80px;” col_rhead_text_text_shadow_style=”preset3″ global_colors_info=”{}” theme_builder_area=”post_content” sticky_enabled=”0″][/dvmd_table_maker_item][/dvmd_table_maker]

Quick Application Guide

Required Pressure

2,000psi

When Applied by Airless Spray Equipment

Recommended Tip Size

.011–.015

Average Coverage Rate

¼–½ GAL

Application

Apply AP-1200 Single-Ply Rinseable Primer / Cleaner with a 2-3 gallon pressure sprayer at a rate of 300-400 square feet per gallon. Allow the material to stand for 15-20 minutes to wet out and react with the single-ply surface. High-pressure rinse the surface with a minimum of 2,000 psi washer, keeping the tip within 12” of the surface.

Use a squeegee to push the excess water towards the drains. After the roof is cleaned, the surface will be jet black in appearance. If it appears dull and weathered, the process must be repeated. Surface must be dry before the coating application. Single-ply substrate must be coated within 5 days of this application.

Preparation of Substrate

Remove all visible dirt and debris by broom or air blower prior to application. Refer to the Armour Proof Coatings Specification for detailed instructions on how to prepare the specific substrate.

Limitations and Precautions

Do not apply AP-1200 when ambient air and substrate temperatures fall below 50°F, or if inclement weather is forecasted. Do not apply if ambient temperature will drop below 32°F or dew will settle before coating is allowed to dry. Do not store sealed containers in prolonged sunlight. Wear rubber gloves and eye protection when working with AP-1200. PROTECT FROM FREEZING DURING SHIPMENT AND STORAGE. Do not store material at temperatures below 45°F. It will freeze and become unusable at temperatures below 32°F.

Application Information

2000″ col_column_max_width=”1fr” col_icon_size=”28px” col_tcell_cell_align_horz=”center” col_tcell_cell_align_vert=”center” col_rhead_cell_align_horz=”center” col_rhead_cell_align_vert=”center” _builder_version=”4.20.2″ _module_preset=”default” col_chead_text_font=”|||on|||||” col_rhead_text_font_size=”0px” global_colors_info=”{}” theme_builder_area=”post_content”][/dvmd_table_maker_item][dvmd_table_maker_item col_label=”Info 2″ col_content=”Coverage Rate Gal/100 Sq.Ft.

¼–½” col_column_max_width=”1fr” col_icon_size=”28px” col_tcell_cell_align_horz=”center” col_tcell_cell_align_vert=”center” col_rhead_cell_align_horz=”center” col_rhead_cell_align_vert=”center” _builder_version=”4.20.2″ _module_preset=”default” col_chead_text_font=”|||on|||||” col_rhead_text_font_size=”0px” global_colors_info=”{}” theme_builder_area=”post_content”][/dvmd_table_maker_item][dvmd_table_maker_item col_label=”Info 3″ col_content=”Tip Size

.011–.015%22″ col_column_max_width=”1fr” col_icon_size=”28px” col_tcell_cell_align_horz=”center” col_tcell_cell_align_vert=”center” col_rhead_cell_align_horz=”center” col_rhead_cell_align_vert=”center” _builder_version=”4.20.2″ _module_preset=”default” col_chead_text_font=”|||on|||||” col_rhead_text_font_size=”0px” global_colors_info=”{}” theme_builder_area=”post_content”][/dvmd_table_maker_item][dvmd_table_maker_item col_label=”Info 4″ col_content=”Let Stand for

15–20 Mins” col_column_max_width=”1fr” col_icon_size=”28px” col_tcell_cell_align_horz=”center” col_tcell_cell_align_vert=”center” col_rhead_cell_align_horz=”center” col_rhead_cell_align_vert=”center” _builder_version=”4.20.2″ _module_preset=”default” col_chead_text_font=”|||on|||||” col_rhead_text_font_size=”0px” global_colors_info=”{}” theme_builder_area=”post_content”][/dvmd_table_maker_item][/dvmd_table_maker]

Use as Part of a System with these products:

AP-3100

Acrylic Base Coat

AP-3200

Acrylic Finish Coat

AP-3300

Acrylic Finish Coat (Colors)

Product Information

Sizes Available

Tools Needed

DATA SHEETS

Grow Your Roofing Business

Become an approved applicator of our Armour Proof Coatings systems and gain the perks of being a trusted and approved contractor. Benefits include project referrals, marketing assistance, product trainings & more!

Have Additional Questions About AP-1100 Rust Inhibiting Primer?

Looking for information on Warranted Roof Coating Systems?

Have a product specialist reach out to answer any questions you have.

Please fill out the below form completely and we’ll be happy to get in touch with you!